Ball Bearings play a crucial role in various machinery and equipment. They reduce friction between moving parts, allowing for smoother operation. Different types of ball bearings excel in specific applications. This diversity is essential for engineers and designers.

Each ball bearing type is designed with unique features. For example, deep groove ball bearings are versatile and commonly used in electric motors. Thrust ball bearings, on the other hand, are ideal for applications requiring high axial loads. Understanding these differences can enhance performance and durability.

Ball bearings can also face challenges. Selection errors can lead to inefficiencies or early wear. Engineers must carefully consider their options. The right ball bearing can optimize machine performance, while the wrong choice may result in costly repairs. Reflecting on these aspects is vital for successful applications.

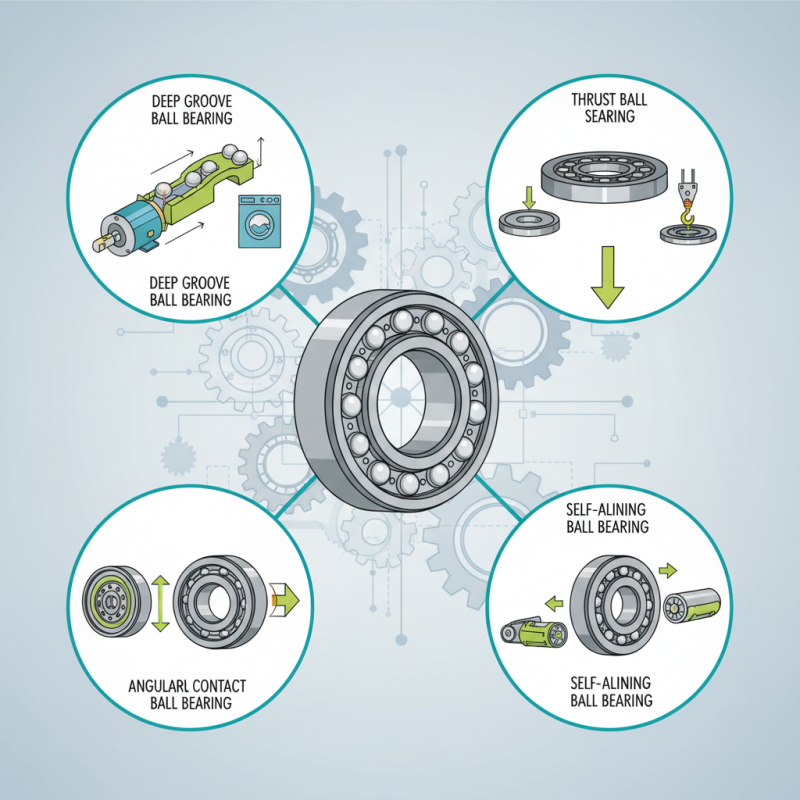

Ball bearings are crucial components in various machines. They reduce friction between moving parts. Different types of ball bearings serve specific purposes across multiple industries. The most common variations include deep groove, angular contact, and thrust ball bearings. Each type is engineered for distinct applications.

Deep groove ball bearings are versatile. They handle radial and axial loads. According to industry reports, they account for over 50% of the ball bearing market. Their widespread use is due to their reliability in motors and machinery. However, their performance can drop in high-speed applications.

Angular contact ball bearings are distinct. They can support higher axial loads. They are ideal for high-speed applications. Yet, their complexity can lead to installation challenges. Thrust ball bearings, on the other hand, support axial loads only. They are used in applications like automotive transmissions. The selection of the right type can significantly affect machine efficiency, making proper evaluation critical.

This chart illustrates the different types of ball bearings and their relative usage frequency in various applications. Deep groove ball bearings are the most commonly used, followed by angular contact and self-aligning ball bearings, highlighting their versatility across various industries.

Deep groove ball bearings are among the most widely used types of bearings. Their simple design allows for high versatility. They can support both radial and axial loads. These bearings are commonly found in electric motors, automotive applications, and household appliances. Their ability to operate at high speeds makes them ideal for many machines.

When choosing deep groove ball bearings, consider the operating environment. Moisture and dust can affect performance. Sealed or shielded options can provide extra protection. Always check for compatibility with your specific application.

Tips: Regular maintenance is key. Inspect bearings for wear or damage. Proper lubrication extends their lifespan. If you notice unusual noise or heat, check them immediately.

While deep groove ball bearings perform well, they are not always perfect. Some applications may require specialized bearings. It's essential to evaluate needs carefully. Experimenting with different types can lead to better results.

Angular contact ball bearings play a crucial role in various mechanical applications. They are designed to withstand combined radial and axial loads. This unique feature sets them apart from standard ball bearings. Studies indicate that these bearings can handle higher loads due to their contact angle. Typical contact angles range from 15 to 40 degrees. The specific angle influences their load capacity and speed.

In practical terms, angular contact ball bearings are often found in industries such as aerospace, automotive, and robotics. For example, in high-speed spindle applications, they can improve performance and longevity. A report by the International Journal of Engineering Research highlights that proper angular alignment significantly enhances efficiency. However, misalignment can result in premature failure and increased operational costs.

With continuous advancements in technology, the demand for angular contact ball bearings is expected to rise. Yet, manufacturers must address challenges such as material fatigue and lubrication issues. These factors are crucial for ensuring reliability. Baker Hughes reports that the global bearing market is projected to grow by over 6% annually. This growth emphasizes a need for improved designs and materials to meet industry demands.

Self-aligning ball bearings play a crucial role in various industrial applications. Their unique design allows for misalignment between the shaft and housing. This feature significantly reduces wear and tear. According to industry reports, these bearings can extend equipment life by up to 30%. They are often used in agricultural machinery, conveyors, and electric motors.

The benefits of self-aligning ball bearings are impressive. They can handle greater loads due to their dual-row design. This setup also allows for better vibration absorption. It is vital to consider installation and maintenance. Proper alignment during installation is essential. Misalignment can lead to premature failure.

Tips: Regularly check for signs of wear. Replace bearings before failure occurs. Vibration analysis can help detect issues early. Monitoring performance may save costs in the long run. Always consult with a professional for complex installations. Keep in mind that not all applications require self-aligning bearings. Assess your needs carefully.

Thrust ball bearings play a crucial role in various rotational systems, particularly in applications requiring axial load handling. These components are specifically designed to accommodate loads along the axis of rotation. A study by the American Society of Mechanical Engineers (ASME) indicates that thrust ball bearings can support axial loads up to 2,200 pounds in some configurations. This makes them ideal for use in machinery like turbines and automotive applications.

In industrial settings, thrust ball bearings help reduce friction. This boosts efficiency, which is essential in performance-driven operations. For example, in heavy machinery, the failure of a thrust ball bearing can lead to significant downtime. A report from the International Journal of Engineering Research highlights that improper installation or selection of these bearings can lead to serious mechanical issues. Some engineers may overlook the importance of precise specifications, leading to operational inefficiencies.

Moreover, thrust ball bearings are commonly used in sectors like aerospace and robotics. These sectors require components that can operate under extreme conditions. Recognizing their limitations is key. They may not perform well in environments with high contamination. Engineers must ensure regular maintenance to optimize their lifespan. This constant need for oversight emphasizes the challenges in managing and operating rotational systems effectively.