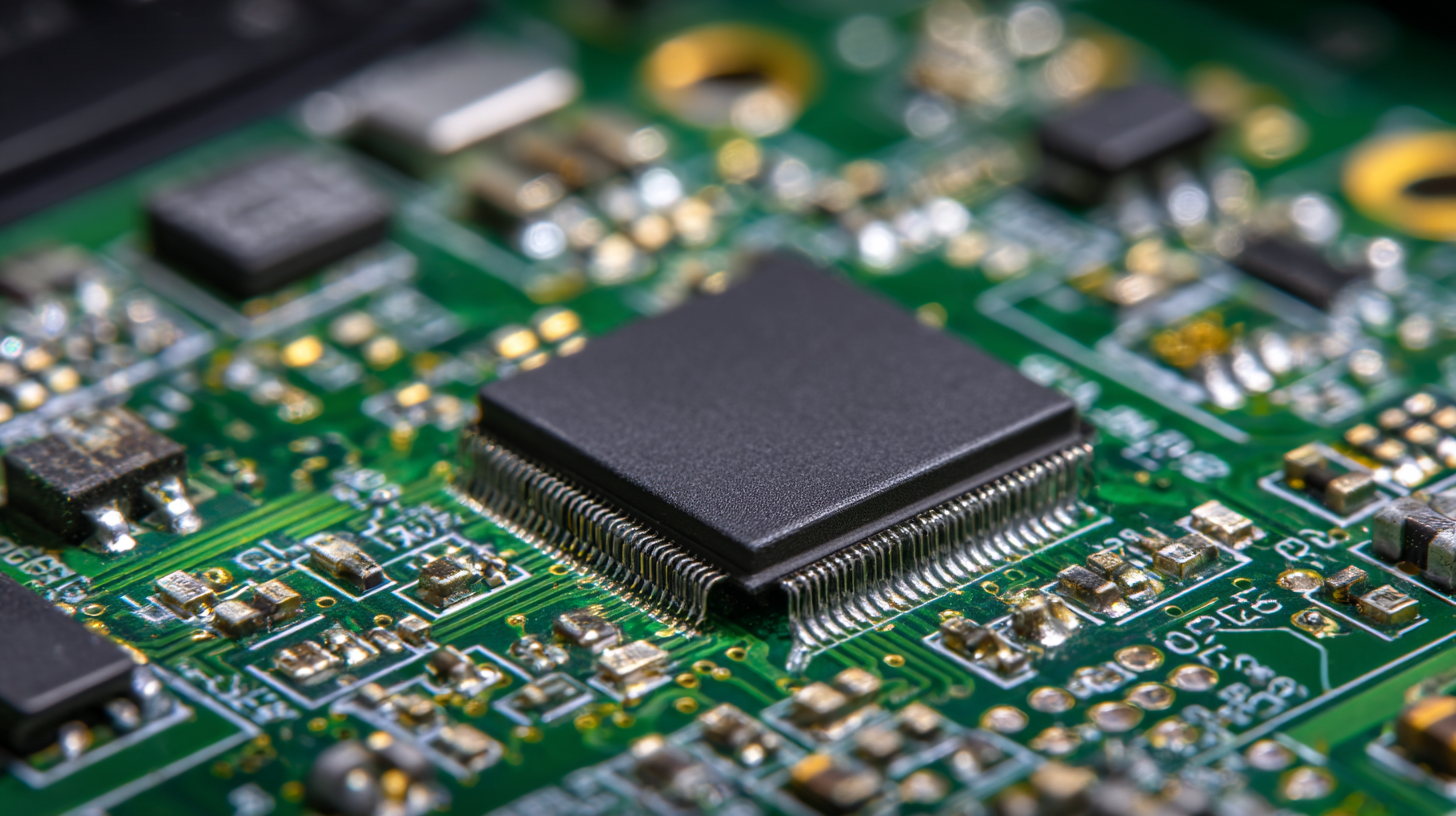

In the rapidly evolving landscape of modern electronics, the significance of Prototype PCB Boards cannot be overstated. According to a recent report by MarketsandMarkets, the global printed circuit board (PCB) market is projected to grow from $64.73 billion in 2022 to $95.30 billion by 2027, at a compound annual growth rate (CAGR) of 8.0%. This surge underscores the pivotal role that prototyping plays in the design and development phase of electronic devices. Prototype PCB Boards serve as crucial tools for engineers and designers, allowing them to test and refine their concepts before mass production, thereby minimizing risks and reducing time-to-market. As devices become increasingly complex and integrated, the demand for reliable and efficient prototype solutions has never been greater, making the understanding and utilization of the best prototype PCB boards imperative for achieving innovative excellence in the electronics sector.

The evolution of prototype PCB boards has been pivotal in shaping the landscape of modern electronics. Over the past few decades, the electronics industry has witnessed a transformative shift due to advancements in technology and materials.

According to a report by PCB Design Magazine, the global PCB market was valued at approximately $60 billion in 2021 and is projected to reach $80 billion by 2026, primarily driven by the increasing demand for faster and more efficient prototype designs. This growth underscores the significance of prototype PCBs, which serve as critical tools for engineers to verify designs, reduce manufacturability risks, and expedite time-to-market.

In recent years, the complexity of electronic devices has increased exponentially, prompting manufacturers to adopt higher-density interconnections and multi-layer designs. A survey conducted by IPC (Association Connecting Electronics Industries) indicates that nearly 80% of electronics companies have shifted towards using advanced prototype PCB technologies, such as HDI (High-Density Interconnector) boards and flexible PCBs, to accommodate smaller form factors and enhance performance. These advancements not only facilitate the development of innovative products but also enable rapid iterations, ensuring that today's electronics can meet the fast-paced demands of consumer markets and technological advancements.

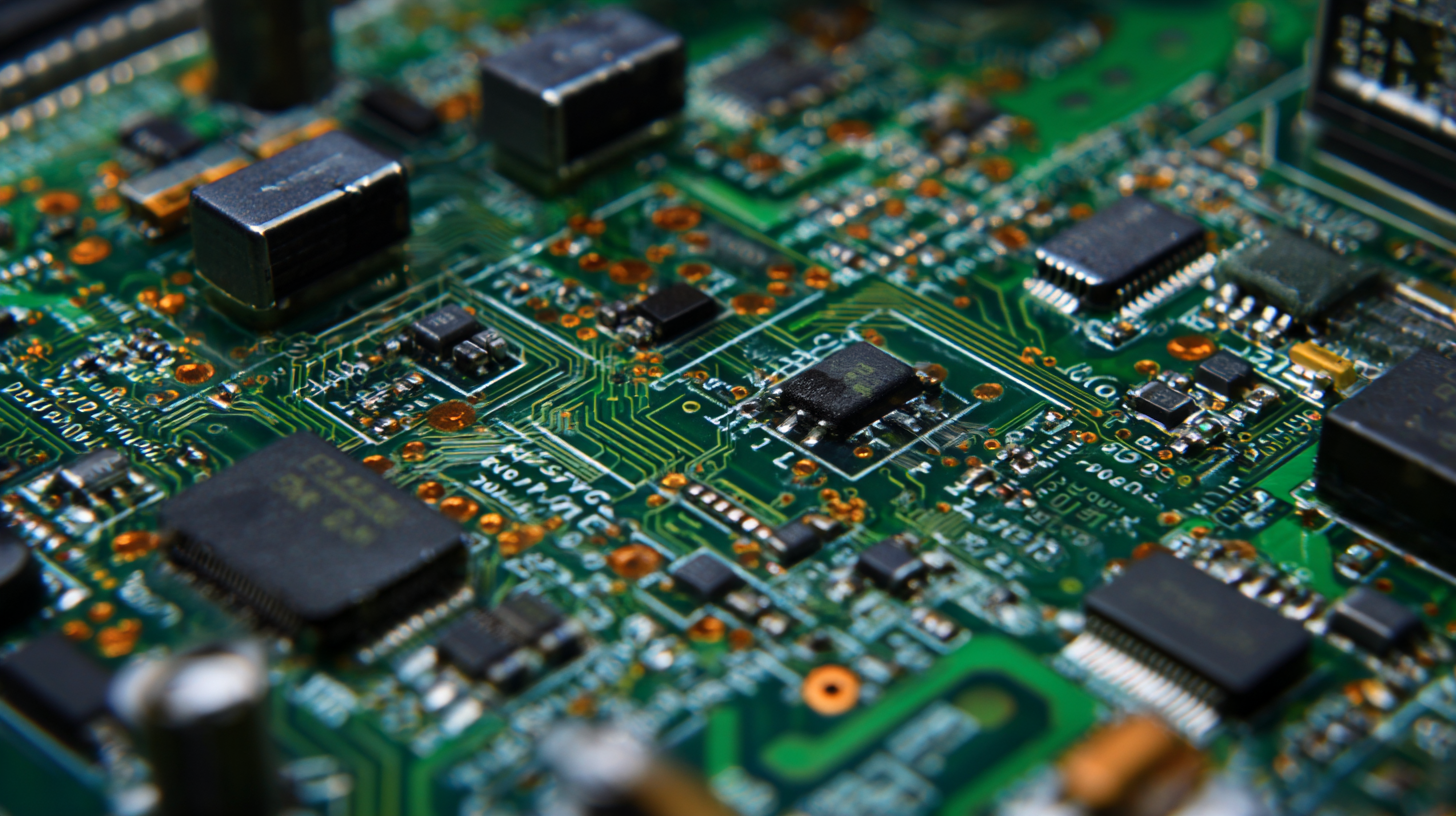

In the realm of modern electronics, the role of prototype PCB boards is paramount across various industries. These boards serve as the blueprint for electronic devices, enabling designers to test and validate their concepts before full-scale production. Key applications of prototype PCBs can be found in sectors such as consumer electronics, automotive, telecommunications, and medical devices. Each of these industries leverages the agility and adaptability of prototype PCBs to innovate products that meet stringent performance and regulatory standards.

In the realm of modern electronics, the role of prototype PCB boards is paramount across various industries. These boards serve as the blueprint for electronic devices, enabling designers to test and validate their concepts before full-scale production. Key applications of prototype PCBs can be found in sectors such as consumer electronics, automotive, telecommunications, and medical devices. Each of these industries leverages the agility and adaptability of prototype PCBs to innovate products that meet stringent performance and regulatory standards.

When creating prototype PCBs, it’s essential to focus on a few critical tips. First, consider the material selection carefully; using high-frequency laminates can significantly enhance signal integrity in RF applications. Additionally, employ design software that supports simulation to preemptively address issues like power distribution and thermal performance. Finally, perform thorough testing of the prototype to identify potential failure points early in the design process.

In medical technology, for instance, the precision of prototype PCBs can directly impact patient safety and device efficacy. Rapid prototyping facilitates the iterative design process, allowing engineers to refine their devices quickly based on real-world feedback. As industries continue to evolve, the importance of high-quality prototype PCB boards will only grow, leading to more reliable and innovative electronic solutions.

When selecting the right prototype PCB for your project, the first step is to define your specific requirements. Consider the parameters of your electronics, such as size limitations, the complexity of the circuitry, and power requirements. Assess whether you need a single-sided or double-sided PCB and if multilayer boards might be necessary for your application. Clear specifications will greatly streamline the design process and help in communicating effectively with manufacturers.

Next, research potential manufacturers that specialize in PCB prototypes. Look for companies with a proven track record in quality and timely delivery. Read reviews and case studies to gauge their expertise, particularly in your specific area of electronics. Requesting samples can also be beneficial to evaluate the quality of their work firsthand. Finally, consider their support capabilities; having responsive technical support can be crucial during the development phase to troubleshoot any issues that arise. By following these steps, you can ensure that your selection aligns with the demands of your project, ultimately leading to a more successful final product.

Designing prototype PCBs (Printed Circuit Boards) poses several challenges, especially as electronic devices become increasingly complex. Engineers often face issues such as signal integrity, thermal management, and manufacturing constraints, which can hinder the development of efficient prototypes. To navigate these hurdles, adopting innovative Electronic Design Automation (EDA) tools is crucial. Recent advancements in EDA solutions have been designed specifically to simplify the design and analysis processes of complex circuits, including emerging 2.5D and 3D IC technologies. These tools enable designers to validate their prototypes quickly and predict performance outcomes effectively, thus expediting the iterative design process.

Moreover, the integration of multi-physical environments in PCB design can help engineers address the multifaceted challenges presented by modern electronics. The ability to simulate various operational conditions and assess potential conflicts in real time allows teams to refine their designs with greater accuracy. By leveraging the latest EDA innovations, including features that enhance automation and facilitate collaboration, designers can overcome obstacles and achieve higher quality prototypes faster, ultimately contributing to the rapid development of cutting-edge electronic products.

This chart illustrates the common challenges faced in designing prototype PCBs and the significance of overcoming them for effective electronic development.

In the evolving landscape of electronics, prototype PCB technology is crucial for innovation and development. As indicated by recent market analyses, the printed circuit board (PCB) industry plays a foundational role in the electronics sector, projected to experience significant growth from 2022 to 2033. This growth reflects the increasing complexity of electronic devices, which demand more advanced prototyping technologies to ensure efficiency and reliability. For instance, the global market for electronic manufacturing services is anticipated to expand, highlighting the necessity for high-quality prototype PCBs in product development cycles.

One promising trend is the rise of laser direct imaging (LDI) technology, which offers enhanced precision in PCB production. The global LDI market is projected to reach $873 million by 2025, indicating a strong shift towards more innovative fabrication techniques. This technology not only improves the accuracy of circuit designs but also reduces production times, thereby accelerating the overall development process.

Tips: When selecting a prototype PCB board, consider the intended application to ensure compatibility and efficiency. Additionally, staying informed about emerging technologies, such as LDI, can provide competitive advantages in the fast-paced electronics market. Finally, collaborating with manufacturers who prioritize advanced PCB technologies will streamline your product development journey, allowing for quicker iterations and improved designs.