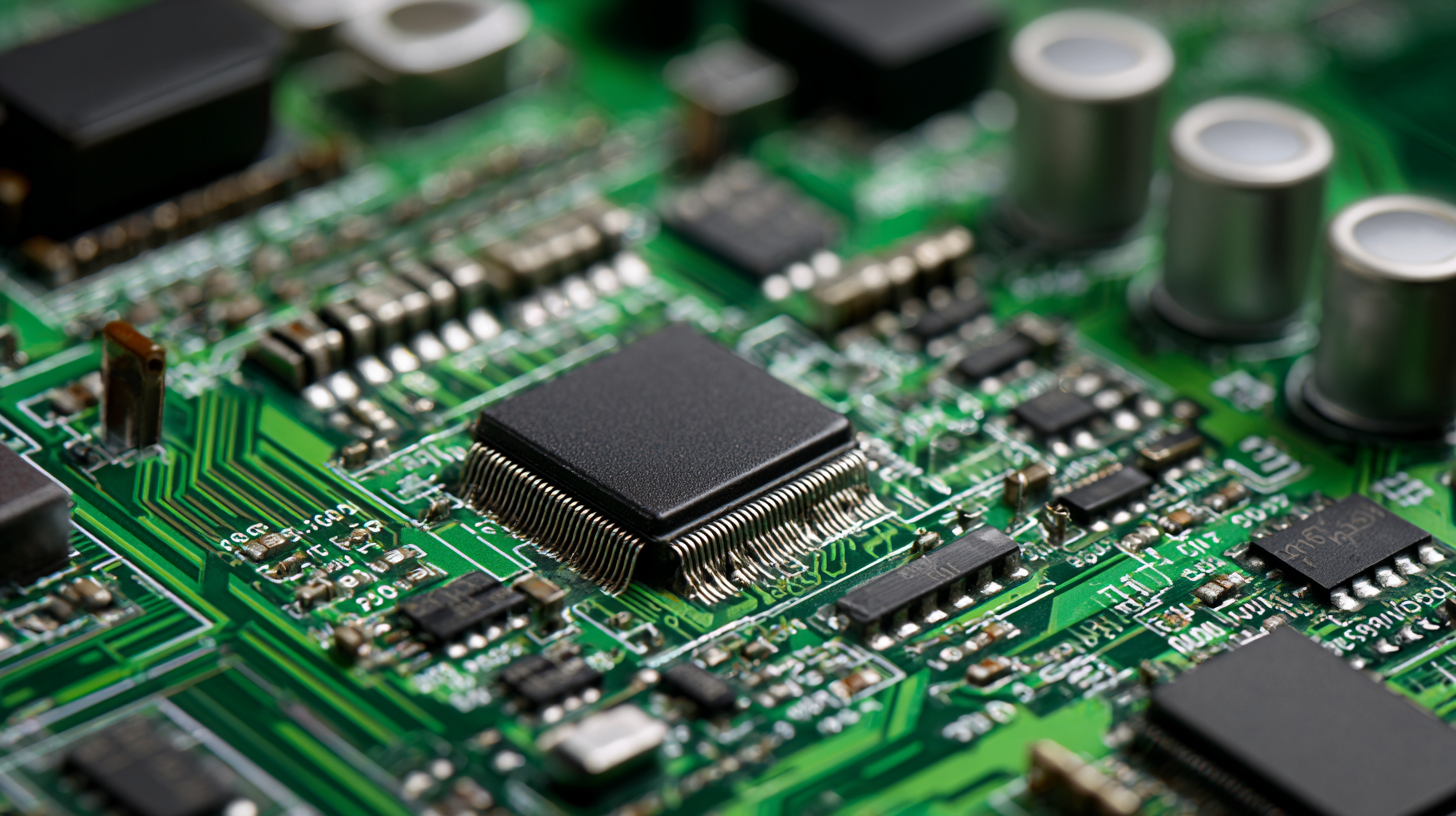

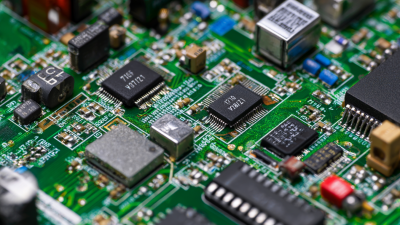

In the fast-evolving landscape of electronics, selecting the right circuit board fabrication service is critical for the success of any project. As industries increasingly rely on sophisticated electronic devices, the demand for high-quality circuit board fabrication has surged dramatically. According to a recent report by Research and Markets, the global printed circuit board (PCB) market is projected to reach USD 85.4 billion by 2027, growing at a CAGR of 4.48% from 2020 to 2027. This growth signals the need for manufacturers and developers to choose fabrication services that not only meet their design specifications but also align with industry standards for quality and efficiency.

When embarking on a project, understanding the nuances of circuit board fabrication can significantly impact performance, reliability, and production costs. Factors such as the type of materials used, manufacturing processes, and the service provider's certifications must be carefully evaluated. A study published in the International Journal of Electronics and Electrical Engineering highlights that nearly 70% of electronic product failures are attributed to poor-quality PCBs. Thus, refining the selection process for a circuit board fabrication service is essential to mitigate risks and enhance the durability of electronic products, ultimately leading to increased satisfaction and profitability in an increasingly competitive market.

When selecting a circuit board fabrication service for your project, it is crucial to consider several key factors that can significantly influence the outcome. First and foremost, evaluate the manufacturer’s capabilities in handling your specific design requirements, including the complexity of the PCB and the materials used. Ensure that they offer advanced technologies such as multi-layer boards and high-frequency capabilities if your project demands them. Additionally, inquire about their quality assurance processes, as adherence to industry standards is vital for the longevity and reliability of your circuits.

When selecting a circuit board fabrication service for your project, it is crucial to consider several key factors that can significantly influence the outcome. First and foremost, evaluate the manufacturer’s capabilities in handling your specific design requirements, including the complexity of the PCB and the materials used. Ensure that they offer advanced technologies such as multi-layer boards and high-frequency capabilities if your project demands them. Additionally, inquire about their quality assurance processes, as adherence to industry standards is vital for the longevity and reliability of your circuits.

Another important aspect is the lead time for production. Depending on your project timeline, a fabrication service that can deliver quickly without compromising quality may be essential. Consider the manufacturer’s flexibility regarding small batch sizes or prototypes, which can be valuable for testing phases before mass production. Lastly, assess customer service and support; a responsive team can help navigate any challenges that arise during the fabrication process, ensuring a smoother experience and a successful project outcome.

When selecting a circuit board fabrication service, evaluating the quality standards and certifications of potential fabricators is crucial. Reputable manufacturers often adhere to recognized standards, such as IPC-A-600 for inspection of printed boards and ISO 9001 for quality management systems. These certifications not only indicate a commitment to quality but also reflect the fabricator's capability to meet specific industry requirements. A fabricator with these credentials is likely to implement rigorous quality control processes, ensuring that the boards produced are reliable and meet your project's standards.

In addition to general quality certifications, it is essential to consider specialized certifications relevant to your project’s unique needs. For example, if the circuit boards will be used in medical applications, certifications such as ISO 13485 can be vital, as they ensure compliance with strict regulatory standards. By thoroughly examining the quality standards and certifications, you can gauge a fabricator's expertise and reliability, ultimately contributing to the success of your project. Engaging with a fabricator that prioritizes quality can minimize the risks of production defects and enhance overall project efficiency.

| Fabricator Criteria | Description | Standard/Certification | Importance Level |

|---|---|---|---|

| ISO 9001 Certification | Quality management systems ensuring consistent quality | ISO 9001 | High |

| IPC Standards Compliance | Standards for PCB manufacturing and assembly | IPC-A-600, IPC-6012 | High |

| RoHS Compliance | Restriction of hazardous substances in electronic equipment | RoHS | Medium |

| UL Certification | Safety standards for electrical devices and components | UL 94 | High |

| Environmental Compliance | Adherence to environmental standards and regulations | ISO 14001 | Medium |

When selecting a circuit board fabrication service, comparing lead times and production capacities among various providers is crucial. According to a recent report from IPC, the average lead time for PCB manufacturing has decreased to about 10-14 days, with high-quality providers offering expedited services that can cut this time down to under a week. Understanding these timelines can ensure that your project stays on schedule, especially for industries that require rapid prototyping or quick turnaround times due to market competition.

Tip: Always ask your potential PCB manufacturer about their production capacities and whether they can handle your project's volume consistently. Many providers have maximum limitations that can affect long-term projects, so it's essential to verify their capabilities thoroughly. Additionally, consider manufacturers that offer flexible production scalability, allowing you to easily increase orders as your project's needs grow.

Moreover, research tools like the Design for Manufacturing (DFM) checklist can help identify potential bottlenecks in your project. As per a study by Deloitte, optimizing the manufacturing process can enhance production efficiency by up to 30%. Collaborating with a fabricator that prioritizes these efficiencies can lead to a smoother workflow and higher-quality end products. Always ensure that your chosen provider aligns not just with your lead time requirements, but also with your long-term production needs.

When selecting a circuit board fabrication service, understanding the cost structures and potential hidden fees is crucial. Recent industry reports indicate that PCB fabrication costs are influenced significantly by factors such as material selection, complexity of the design, and volume of production. A study by IPC, an industry association, highlights that approximately 40% of manufacturers experience unexpected costs during the PCB procurement process due to inadequate communication with suppliers regarding project specifications.

Hidden fees can stem from several sources, including setup charges, expedited shipping costs, and charges for revisions. For instance, if a project requires quick turnaround times, companies may face premium charges that inflate the overall budget significantly. A report from TechSearch International noted that such fees can add up to 15-30% over the initial quote, especially for low-volume orders or intricate designs. Therefore, it is essential for project managers to ask for transparent pricing breakdowns and clarify potential additional costs during negotiations to avoid budget overruns.

When selecting a circuit board fabrication service, the importance of customer support and communication cannot be overstated. Efficient communication channels can significantly streamline the development process, ensuring that any issues are promptly addressed. According to a recent industry outlook report, clients who experience high levels of support during PCB projects are 30% more likely to achieve their project's timelines and overall satisfaction. This highlights the value of choosing a service that prioritizes customer interactions.

Additionally, as the PCB industry anticipates growth from 2025 to 2027, driven by increasing investments and technological advancements, businesses that offer responsive and adaptive customer service will stand out. Companies that understand the complexities of PCB assembly and provide continuous support can effectively assist clients in navigating potential challenges. The ability to maintain open lines of communication not only fosters collaboration but also enhances the overall quality of the product, making it essential for any project’s success. Thus, evaluating a fabrication service based on these criteria can lead to more effective project outcomes and **long-term partnerships.